|

|||

|

|||

|

|

|

604 921 9185 |

|

|

|

|

|

|

|

|

|

|

|

South Coast Sundecks & Exteriors is a vancouver vinyl decking installation company and vinyl deck builder. We provide our clients with remarkable & efficient results that support & exceed all vinyl deck membrane warranties and all Provincial B.C. Building Codes. |  |

|

Everything Waterproof Vinyl Decking Membranes for Decks |  |

|

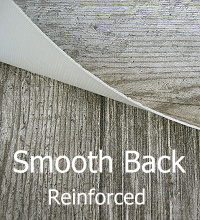

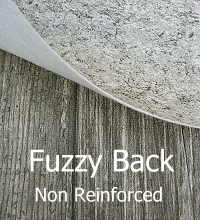

Two types of vinyl decking membranes

There are two 'common' modern types of waterpoof vinyl decking membranes widely used today in the marketplace for consumers to choose from. Both are constructed from PVC (Polyvinyl chloride) and are commonly referred to as 'fluffy or fuzzy back' vinyl and 'slick or smooth back' vinyl that describes the appearance of what you see on the back of the vinyl membrane sheeting. Most if not all Fuzzy back vinyl decking is Non reinforced where most Smooth back vinyl decking is reinforced in the core. There is also a 'scrum back' vinyl or what appears to be a mesh backing vinyl but its purpose is so that the solvent based glues will stick to the vinyl and don't really offer tear resistance or product strenght integrity.

Most quality vinyl membranes range in thickness from 45mil to 66mil.

It is important to remember that the quality of the vinyl and its construction is paramount to its thickness which is a miniumum requirement as some lower cost vinyls will perform much differently and may not pass critical Building code and North American testing requirements. Some vinyl suppliers have had catastrophic product failures from the importation of cheap off shore vinyl membranes where the plasticization properties have broken down making the vinyl soft and sticky.

All Building code approved vinyl sheet decking installations require that the adjoining sheets be overlapped by a minimum of 1" and have these

seams hot air welded together in order to fuse or melt the membrane into a single waterproof membrane covering your deck.

|  |

|

Fuzzy back vinyl decking membranes

have a white polyester backing imbeded into the vinyl that allows a 'contact glue' to reliably stick to its surface. The application procedure involves applying the contact glue to both the back of the vinyl as well as the surface that it is being bonded to which is usually plywood. Once the two glue covered surfaces make 'contact' they instantly stick to one another. There are different glue variations such as Nitrile or Neoprene based that are used for the installation.

Fuzzy back vinyl decking membranes

have a white polyester backing imbeded into the vinyl that allows a 'contact glue' to reliably stick to its surface. The application procedure involves applying the contact glue to both the back of the vinyl as well as the surface that it is being bonded to which is usually plywood. Once the two glue covered surfaces make 'contact' they instantly stick to one another. There are different glue variations such as Nitrile or Neoprene based that are used for the installation.

Most if not all 'Fuzzy back' vinyl membrane manufacturers Require that the overlapping welded seams to be 'cap welded' aswell to insure a reliable waterproof seal so that any fuzzy backing that isn't burnt off during the seam welding process doesn't wick water and cause pinhole leakage and/or weaken the seam. Welding or 'bleeding' the cap or edge of where you see the two vinyl sheets meet will leave a distinct line or pinstripe that some will find undesirable which is not the case with some smooth back vinyl membranes like Tufdeks Supreme & Designer series vinyls that do not require cap welding. |  |

|

Two types of vinyl decking flashings

You may agree the appearance of another color added by the 3/4" metal strip with screws every 4" that will catch dirt and mildew and make a mess of your fascia boards to be a not very attractive option. Plastic flashing clips also appear like a pinstripe, catch dirt and grime and have a habit of coming off eventually thus allowing the vinyl membrane to peel or curl up overtime.

1) The thicker flashing does not 'ripple' from expansion & contraction in the heat. 2) The thicker flashing allows us to recess the flashing into the plywood with a planer rather than just nailing it to the top surface so there is no 'build up' areas for water to pool and deposit dirt along the deck edge after rainfalls.

3) The vinyl coating allows us to weld the vinyl membrane to the flashing instead of glueing which is much stronger, reliable and eliminates the use of plastic retention clips. 4) It also provides another unique appearance option for our clients with 5 exposed face flashing color choices that can either match your fascia board, house trim or vinyl selection because the vinyl membrane doesn't need to run down the horizontal face of the flashing with this process.

|  |

|

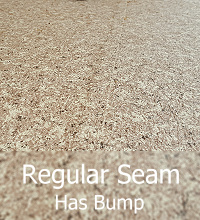

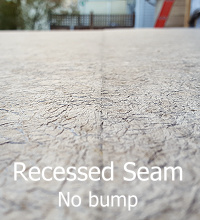

Two types of vinyl decking seams

Because of a much needed B.C. building code revision that now states vinyl membranes for new construction pedestrian traffic should be no less that 60mil these seam bumps have become inadvertently taller that can catch water and leave dirt deposits on low sloped decks.

Other than a visual drawback, table chair legs may catch a little on the bumps aswell as foot traffic crossing back and forth certain areas which may prematurely wear the ink patterns off and highlight the bumps even more.

Our refined procedures and 100% reliable techniques make our overlapping seams hard to find sometimes with certain vinyl colors and makes the entire vinyl deck surface look much more natural. We only offer flush seam service with our smooth back vinyls and the procedure slows down the installation process so there is a tremendous amount of added value if the customer wishes to choose this option.

Seam direction is usually parrallel to the house or the longest span especially if you are using our wood grained viny decking. Sometimes the vinyl can be run perpendicular to the house to reduce product waste or for decks that are improperly sloped to help reduce water sitting along the seams if you don't choose our flush seam options. Keep in mind this scenario does result in more seam bumps and noticeable shadow lines that cross the pedestarian traffic path that can result in premature wear to the ink color on the seam bumps.

Standing water (water pooling) on existing sundecks is from the original structure (deck framing) not being built properly. Vinyl resurfacing and plywood replacement does Not include the re-sloping or alteration of any existing structural components such as the joists of your deck if you have areas where there is standing water or 'pooling'. If you have areas where water is pooling and it bothers you, you must notify us so that we can further identify the problem and include a cost estimate in your quotation and your contract so that we can try to correct these original building defects in a cost effective manner.

Keep in mind there is a fine line between safe non-slip floor traction and product porousness that can attract dirt and mildew quicker that requires constant and longer cleaning times and possibly product discoloration as a result. For example quality vinyl decking that has anti bacterial properties built into the vinyl and some will have a non-slip concave texture rather than a convex texture design that is much easier to stay and keep clean. Some quality vinyl decking membranes like Tufdek vinyl decking has been tested by the National Floor Safety Institute (NFSI) to meet certain safety criteria that is important for wet climates.

|

|

|

We offer the 2 main types of vinyl decking available in the industry Prices include supply and installation

Tufdek Econodek - All colors $9.95 sq ft (Fuzzy backing) 10 year warranty Drip Edge Flashing Options

Tufdek vinyl coated heavy guage - recessed into deck (welded transitions) Seam Options

Regular seam - no cap weld - overlapped by 1" and airwelded - Included Related Services

Vinyl removal & disposal; sand & patch existing plywood $2.00-$3.00 sq ft Project Timing

Average time from Ordering to Installation is 2-6 weeks during busy season

Convenient estimate provided by email with the following criteria: Your deck dimensions or plans, 4 corner deck location pictures, Your Name, Phone Number and City. Site visit required for quotation and order.

|

|

Learn More, See more...

Associated Page Tufdek Vinyl Decking Membranes Associated Page Everything Patio & Deck Surfaces Related page Everything Deck & Patio Railings Related page Everything Deck & Patio Covers Related Page Everything Deck & Patio Building Related page Deck Building Permit information Related page Property Management & Builder Services Visit Featured Projects Pages showing our vinyl decking and building Visit Whats New for you with South Coast Sundecks & Exteriors page Please inquire here or phone 604 921-9185 to book an appointment. |

|

|

|

|

|

|

|

South Coast Sundecks - Your answer to a Remarkable Vinyl Deck |  |

|

Warranties

Testimonials Contractors | Multi Unit |

Designing

Whats New Inspirations |

Request a Quote

Featured Projects Seasonal Incentives |

|

| All page content Copyright South Coast Sundecks & Exteriors Ltd - Everything Waterproof Vinyl Decking Membranes |